Let’s face it, existing roads, bridges and traffic systems weren’t designed for digital retrofitting. Trenching and boring through roads and pavements is disruptive, labour-intensive and expensive. As communication cabling needs surge across ITS corridors, the ability to easily maximise conduit space, minimise disruption, and future-proof networks becomes essential.

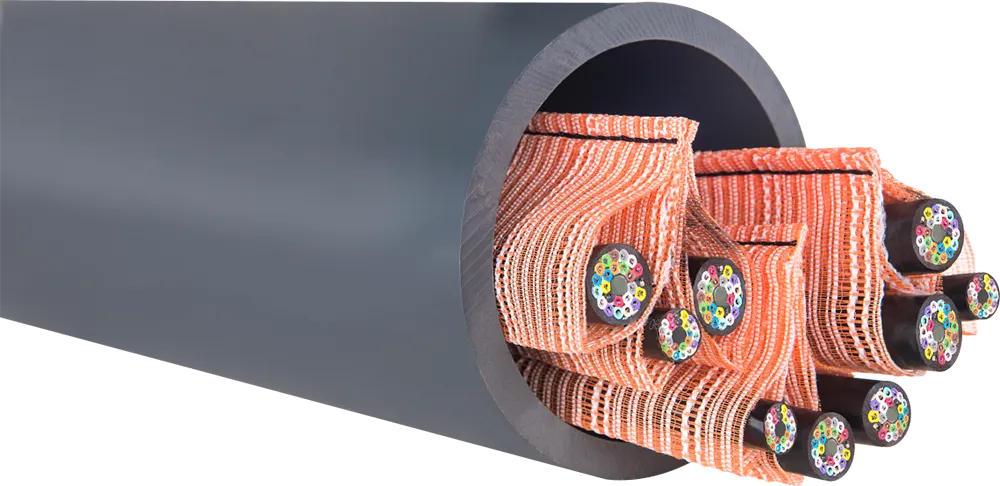

MaxCell will highlight that, whether planning for connected corridors, V2X integration or next-generation traffic systems, the company provides an innovative approach to meet these demands. One of the standout features of MaxCell is its versatility. Available in a variety of sizes and configurations, MaxCell innerduct solutions can be tailored to meet the specific requirements of each project and can increase cable density by 300% or more.

With options that are plenum rated, UL-listed and LSZH (low-smoke zero-halogen), the company’s lightweight and easy-to-handle innerduct can be installed three times faster than traditional HDPE, making MaxCell a cost-effective and time-saving option. MaxCell innerduct weighs only one-eighth of traditional HDPE, significantly reducing transportation costs. When it comes to sustainability, MaxCell states its carbon footprint is 81.24% lower than that of HDPE innerduct.

What’s more, not only does MaxCell support Dig Once initiatives, but the company can also provide a No Dig option by saving remaining empty ducts in congested areas for future bandwidth requirements.

From rail to roadside, the company points out that its innerduct solutions are trusted by DOTs, airports, ports and transit authorities around the world.

Visit the MaxCell stand for product demonstrations and to connect with company experts

Stand 1054