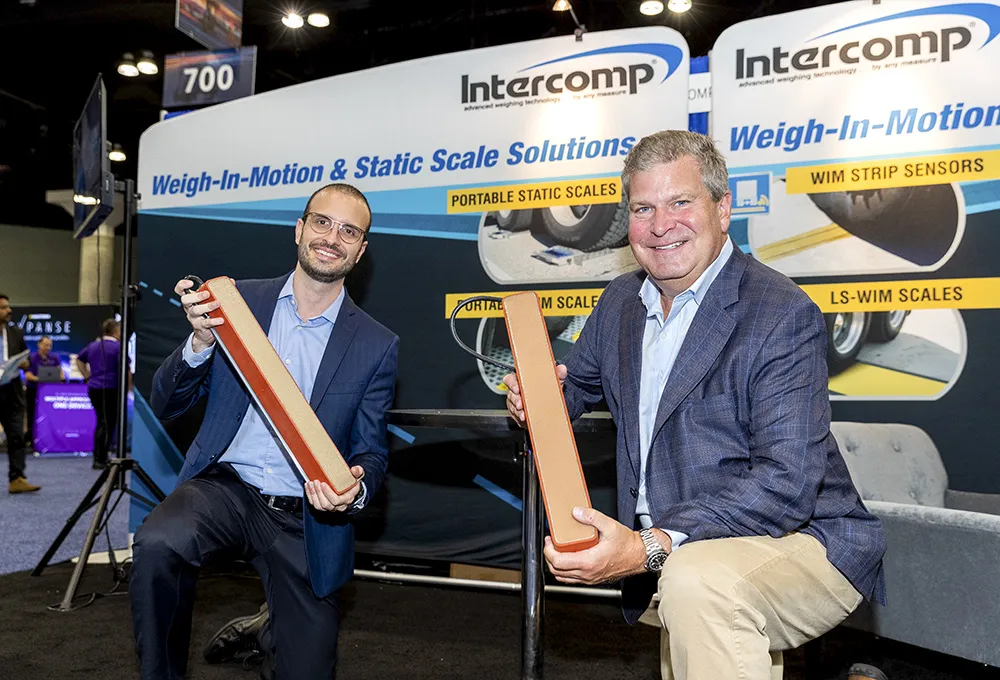

Intercomp is showcasing its continued success with weigh-in-motion (WIM) strip sensors for weight based applications, the company’s sensors and systems have recently been installed in Europe, Asia, and both North and South America.

October 7, 2016

Read time: 1 min

Grouted into three inch (75mm) channels cut into the pavement, the strain gaugebased strip sensors detect axle weights, vehicle weights and use axle spacing to determine vehicle classifications. Operating over a wide range of temperatures, configurations of these sensors are used in data collection, screening for enforcement, tolling (ETC), and industrial applications.

According to Intercomp, its strain gauge-based strip sensors enable accurate weighing technology, usually reserved for static scales, to be used at speeds up to 80mph (130km/h).

Site accuracies exceed COST A(5) and ASTM Type III requirements across a wide range of vehicle speeds. Installed in a vehicle lane within a single day with minimal civil works required, lane closures are kept to a minimum to incorporate and update WIM sites.

Supplied within a complete system or integrated with existing electronics and software platforms, users have the flexibility to incorporate the WIM sensors at standalone sites or within current infrastructure.