Yesterday, Mahindra Reva Electric Vehicles, a part of the US$15.4 billion Mahindra Group, formally inaugurated its manufacturing facility, which is the first platinum rated automobile facility in India. Inaugurating the world-class, energy efficient, green manufacturing facility, Anand Mahindra, chairman and managing director, Mahindra Group unveiled the Group's vision to co-create and shape the "future of mobility".

August 23, 2012

Read time: 3 mins

Yesterday, 6439 Mahindra Reva Electric Vehicles, a part of the US$15.4 billion Mahindra Group, formally inaugurated its manufacturing facility, which is the first platinum rated automobile facility in India. Inaugurating the world-class, energy efficient, green manufacturing facility, Anand Mahindra, chairman and managing director, Mahindra Group unveiled the Group's vision to co-create and shape the "future of mobility".

"We firmly believe that the automobile industry is at an inflection point that will re-shape the way we own and use mobility solutions,” Mahindra said. “This change is being driven by rapidly changing customer needs and dramatic advancements in automotive technologies, including the growing influence of electronics and IT in automobile products and solutions."

Elaborating on the Group's intent to create a movement that will encourage all stakeholders to co-imagine and co-create a shared vision of the future, Mahindra added, "We have tried to capture the critical elements where maximum change will be seen, using a framework of 5 C's. The 5C's, when seen together, define the 'future of mobility'. It is important to understand that the 5 C's don't just apply to cars but rather to the entire automotive value chain and the ecosystem." Mahindra defined the 5C’s framework as, Clean, Convenient, Connected, Clever and Cost Effective.

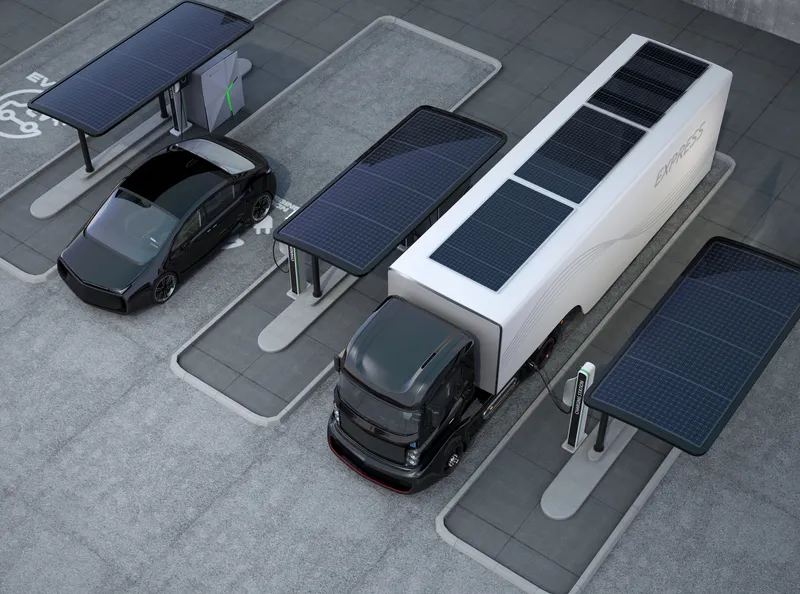

Emphasising the Mahindra Group's ability to rise to the challenge of shaping the future of mobility, Dr. Pawan Goenka, president - AFS, Mahindra & Mahindra and chairman Mahindra Reva Electric Vehicles said, "EVs are being seen as a serious alternative to fossil fuel driven cars and Mahindra wants to take a lead in developing the EV segment and the surrounding ecosystem. The new manufacturing plant is, in a way the first tangible proof point of the future of mobility - this is the first purpose-built, ground-up EV plant in India, the first manufacturing plant to get IGBC platinum rating, the first plant where cars get their first fill using solar power. In fact, this plant will consume the least amount of energy per car build, with one-third of this energy coming from solar power."

Mahindra Reva also unveiled a host of technologies, all of them directly inspired by the vision of the future of mobility.

The technologies showcased include 'Quick2Charge', by which the car can be charged in 15 minutes to run 25 kms, thereby providing customers with increased convenience. In order to tap and use the abundant solar energy for mobility, Mahindra Reva has designed a personal charging unit called 'Sun2Car' which will provide free and clean energy for the lifetime of the car, making it a very cost-effective solution. The technology, 'Car 2 Home' makes it possible to use energy from the car to power a house.

"We firmly believe that the automobile industry is at an inflection point that will re-shape the way we own and use mobility solutions,” Mahindra said. “This change is being driven by rapidly changing customer needs and dramatic advancements in automotive technologies, including the growing influence of electronics and IT in automobile products and solutions."

Elaborating on the Group's intent to create a movement that will encourage all stakeholders to co-imagine and co-create a shared vision of the future, Mahindra added, "We have tried to capture the critical elements where maximum change will be seen, using a framework of 5 C's. The 5C's, when seen together, define the 'future of mobility'. It is important to understand that the 5 C's don't just apply to cars but rather to the entire automotive value chain and the ecosystem." Mahindra defined the 5C’s framework as, Clean, Convenient, Connected, Clever and Cost Effective.

Emphasising the Mahindra Group's ability to rise to the challenge of shaping the future of mobility, Dr. Pawan Goenka, president - AFS, Mahindra & Mahindra and chairman Mahindra Reva Electric Vehicles said, "EVs are being seen as a serious alternative to fossil fuel driven cars and Mahindra wants to take a lead in developing the EV segment and the surrounding ecosystem. The new manufacturing plant is, in a way the first tangible proof point of the future of mobility - this is the first purpose-built, ground-up EV plant in India, the first manufacturing plant to get IGBC platinum rating, the first plant where cars get their first fill using solar power. In fact, this plant will consume the least amount of energy per car build, with one-third of this energy coming from solar power."

Mahindra Reva also unveiled a host of technologies, all of them directly inspired by the vision of the future of mobility.

The technologies showcased include 'Quick2Charge', by which the car can be charged in 15 minutes to run 25 kms, thereby providing customers with increased convenience. In order to tap and use the abundant solar energy for mobility, Mahindra Reva has designed a personal charging unit called 'Sun2Car' which will provide free and clean energy for the lifetime of the car, making it a very cost-effective solution. The technology, 'Car 2 Home' makes it possible to use energy from the car to power a house.