Hyped, a student group at Scotland’s University of Edinburgh, claims to have pushed forward the technology that could make the hyperloop concept a reality.

Hyped says it has produced in the past several months a more efficient linear induction motor (LIM), a stronger and lighter chassis and an improved braking system.

Hyperloop - a proposed network of near-vacuum steel tubes for people and cargo in magnetically levitating pods - could cover the 650km between Edinburgh and London in around 45 minutes, according to advocates of the system. The fastest trains take just under four and half hours.

Hyped said it made serious progress with asynchronous motors this year, removing the need for a rotating rotor which had previously limited the maximum speed.

LIMs with multiple poles help achieve maximum thrust and efficiency while reducing the static end-effects.

A complex modular power system supplies these motors. By separating the power source from the series connection components, Hyped said it has ensured minimum risk for those working on the project.

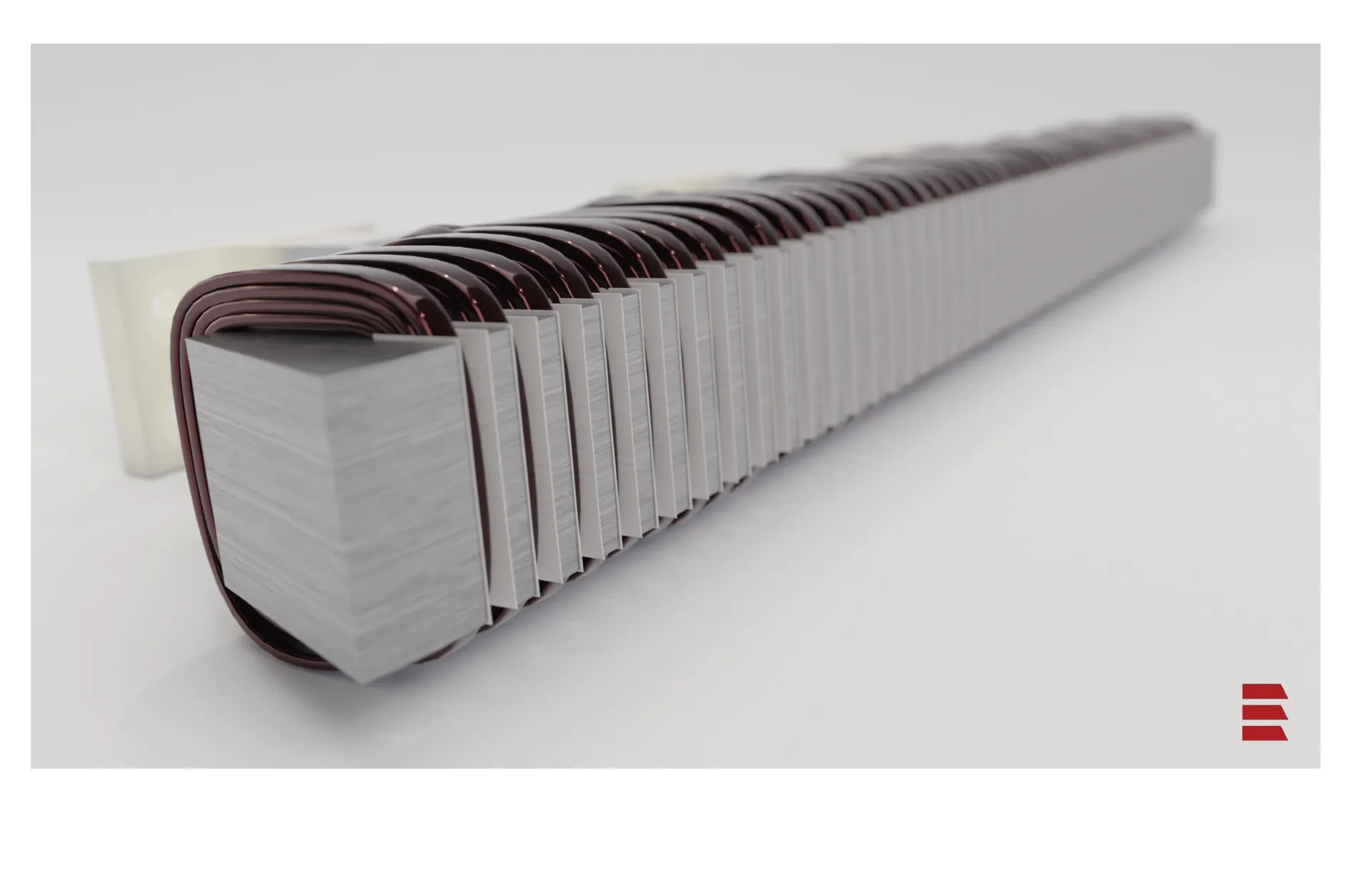

Accommodating the powerful LIMs required an ultra-strong chassis without compromising on weight: Hyped produced a 1.5m-long chassis that weighed just 15kg and was comprised of material from last year’s chassis.

Implementing a sandwich structure of carbon-fibre reinforced polymer laminates around an aluminium honeycomb core had worked very well in the past.

However, due to the large forces of attraction created by the newly improved LIMs, additional stiffening was required and achieved with composite panels.

Epoxies and polyurethanes are typically used to attach the panels. But Hyped’s engineers used a methacrylate adhesive to achieve a 33.2% weight reduction - even with the composite panels added. This resulted in a strong and lightweight structure.

A reliable, strong and compact braking system was achieved this year with a primary system of symmetric, magnetic brakes.

Magnets attached to a moving hyperloop pod will generate a magnetic field that changes relative to the conductive aluminium I-beam. This induces a magnetic field in the rail that will oppose the pod’s motion and decelerate it.

This system doesn’t produce fine particulates during braking because it removes all direct contact, using magnetic forces instead, Hyped says. A secondary system of friction brakes is used for low speeds where magnetic breaking is less effective.